The Beginner’s Guide To Polyurethane

.

About Polyurethane

About Polyurethane

Polyurethanes are one type of a large family of elastic polymers called rubber. Unlike conventional rubber, polyurethanes start out as liquids and can be cast in low-pressure molds. Here at Gallagher, we also process thermoplastic urethanes that lend themselves well to injection molding.

What polyurethane should you be using?

The polyurethanes processed at Gallagher are typically two-component systems: a prepolymer and a curative. We also process compounds with three and sometimes four components to achieve specific properties. For our thermoset compounds, the prepolymers and the curatives are held in separate tanks under vacuum in our meter mix machines. When it’s time to make a part, the prepolymer and curative are mixed and dispensed into a mold. In the mold, a chemical reaction takes place which forms the solid elastomer. The thermoplastic urethanes we use for injection molding are different from the thermoset polyurethanes and are fully reacted prior to our processing operation.

The prepolymers used for urethane processing consist of isocyanate groups that react with either hydroxyl groups or amine groups in the curative. The resultant moiety from the isocyanate-hydroxyl reaction is called a urethane linkage; isocyanate-amine reaction forms what are called a urea linkage. As more and more isocyanate groups in the prepolymer link up with hydroxyl or amine groups in the curative, many urethane linkages are formed and this is where the term polyurethane comes from.

There are many combinations of prepolymers and curatives available which create unique properties in the cured urethane elastomer. Prepolymers are distinguished by the type of isocyanate and the type of polyol that is used to make them. The type of isocyanate used in the prepolymer is the main building block of the polyurethane compound. Here at Gallagher we typically use four different types of isocyanate: MDI, TDI, TODI, and PPDI. Other types are available and we can offer those for specialized applications. The major groups of polyol consist of Polyester, PTMEG Polyether, and Polycaprolactone, each type will produce an elastomer with unique properties.

What Are Polyurethane Elastomers?

Polyurethane elastomers (urethane elastomers) are one type of a large family of elastic polymers called rubber.

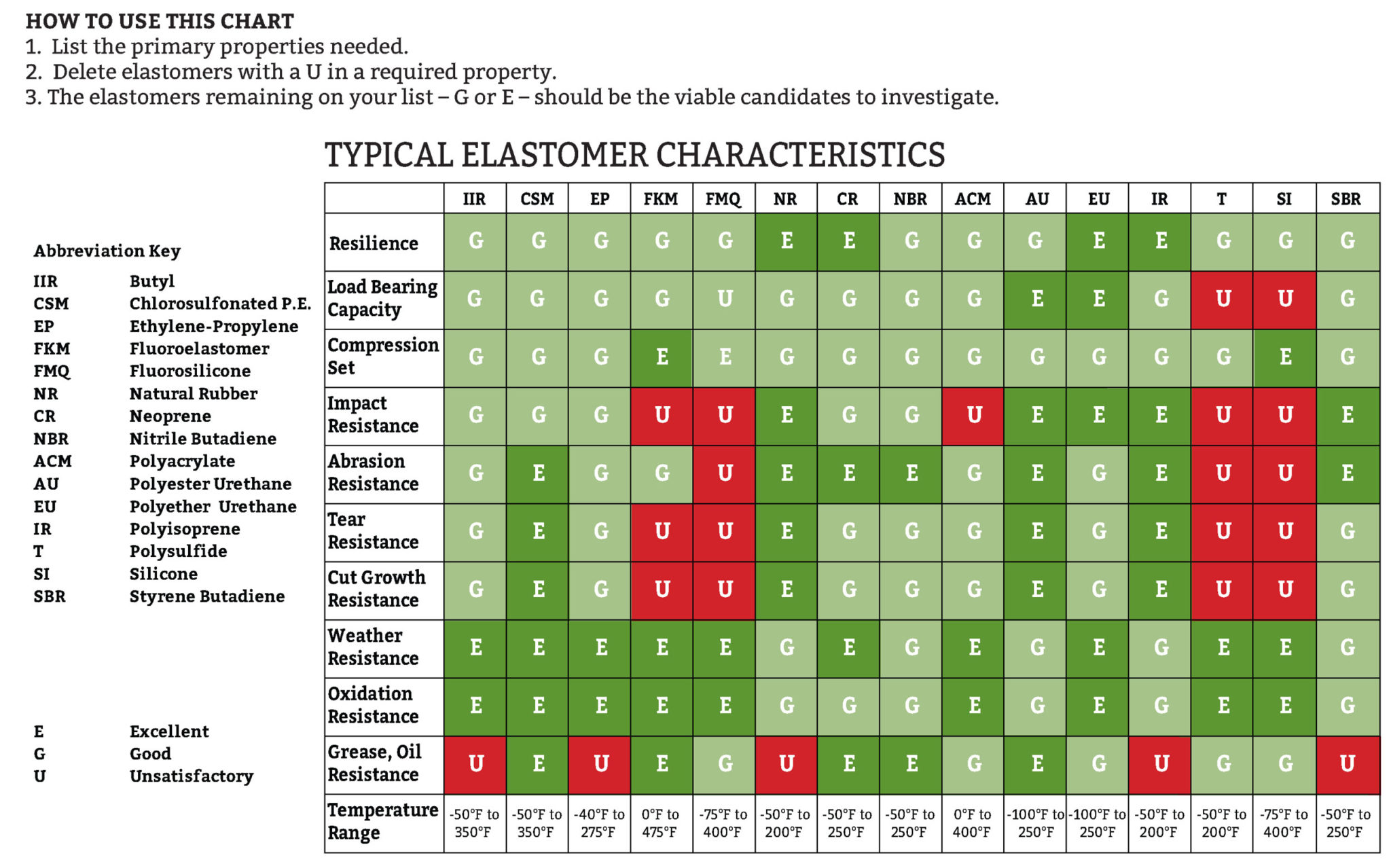

There are 14 types of rubber in general use. All of these polyurethane elastomers have been commercially successful, but they are all different in several ways. The chart below provides a quick initial screening guide of these polyurethane elastomers.

Download this table as a PDF

Isocyanates

- Toluene Diisocyanate (TDI)

- Diphenylmethane Diisocyanate (MDI)

- Paraphenylene Diisocyanate (PPDI)

- Toluidine Diisocyanate (TODI)

- 1,5-Naphthylene Diisocyanate (NDI)

Polyols

- Polyester

- PPG Polyether

- PTMEG Polyether

- Polycaprolactone

- Polycarbonate

Curatives

- 1,4-Butanediol (BD)

- 1,3-Propanediol

- Ethacure 300

- HQEE

- MOCA

While Gallagher Corporation has the technical expertise and equipment to process any of these materials, the combinations most typical to Gallagher include:

- TDI Polyester with hardness ranging from 70A to 70D

- MDI Polyester with hardness ranging from 85A to 95A

- TDI PTMEG Polyether with hardness ranging from 90A to 70D

- MDI PTMEG Polyether with hardness ranging from 60A to 95A

- TDI Polycaprolactone with hardness ranging from 60A to 55D

- NDI Polyester (Vulkollan®) with hardness ranging from 65A to 60D

TDI Polyester materials cured with MOCA produce tough elastomers that have outstanding abrasion resistance and excellent oil and aliphatic solvent resistance.

MDI Polyester materials cured with 1,4-Butanediol produce FDA wet and dry food grade urethanes which are tough, abrasion and tear resistant.

TDI PTMEG Polyether materials cured with MOCA have excellent low-temperature flexibility, excellent dynamic properties are resistant to microbial attack and hydrolysis.

MDI PTMEG Polyether materials cured with 1,4-Butanediol have high resilience (even at low temperatures), great dynamic properties, outstanding hydrolysis resistance and improved resistance to impingement type abrasion. Some MDI Ethers can be formulated to be FDA wet and dry food approved.

TDI Polycaprolactone materials cured with MOCA have better hydrolysis resistance than other polyesters while maintaining great resistance to abrasion. These materials also have great tear strength even at low hardness.

NDI Polyester cured with 1,4-Butanediol is trademarked with the name Vulkollan®. Vulkollan® is an ultra-high performance material that has the highest mechanical load bearing ability and is the best choice in highly dynamic applications.

Polyurethane Technical Data and Design Guide Table of Contents

Section 1: Polyurethane 101

Section 2: Key Polyurethane Properties

- Load Bearing

- Fatigue

- Shear

- Hardness

- Bonding to Metals

- Oil and Chemical Resistance

- Abrasion Resistance

Section 3: Design Considerations & Calculations

- Effect of Loading Conditions

- Shape Factor

- Impact Shock Force

- Hysteresis in Urethane

- Vibration Isolation

- Coefficient of Friction

- Stoichiometry

- Molding Tolerances

- Physical Constants