Designing Polyurethane Products

The following steps in order yield the best approach to design and problem-solving. We encourage you to contact us for help every step of the way.

- Prioritize the properties that are necessary for performance in a given application.

- Material characterization – bring us in at this stage. The urethane elastomers can be tailored to an almost infinite variety of material properties. We can assist in the selection. There is no perfect elastomer for all applications, but there are usually one or two choices that are worthy of prototype testing.

- Establish a prototype test program simulating the operating conditions. Acceleration of testing by increasing cyclic rates or amplitudes beyond the application parameters always results in excessive heat build-up in urethanes and unsatisfactory data.

- Modify the compound or design to correct any deficiencies noted in testing.

- Set up a limited field trial and monitor results.

- Modify compound and design if required.

- Write a material specification for inclusion with design drawings.

Why Choose Gallagher For Your Custom Cast Urethane Needs?

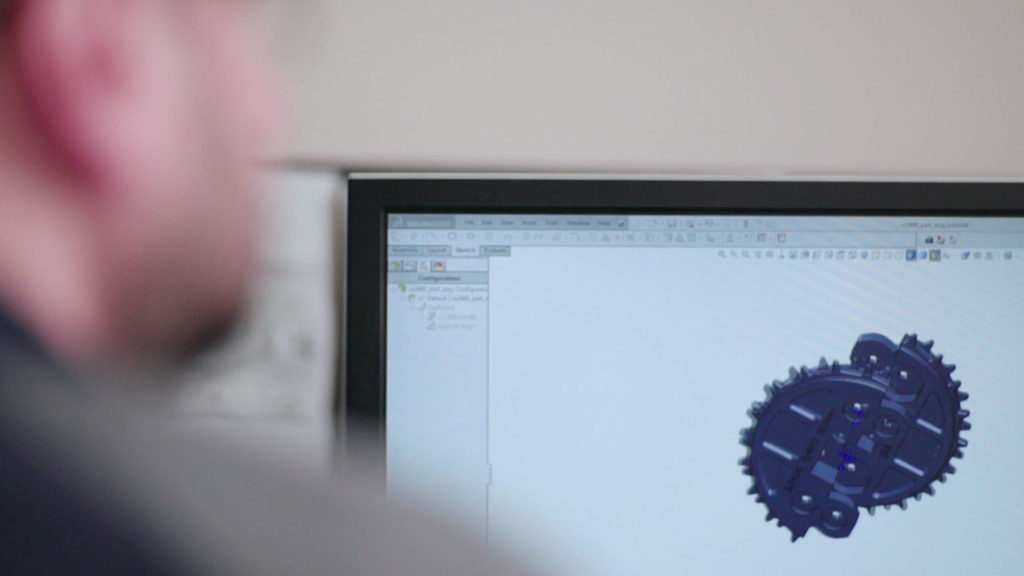

Continuous Advancements in Polyurethane Expertise and Equipment

Bring Gallagher even the trickiest requirements of your most important components, and time after time, we turn them into success at our 100,000-square-foot, ISO-certified facility in Gurnee, Illinois. Meanwhile, as your demands keep getting tougher, we’re always reinvesting in our business, constantly enhancing our expertise and continuously improving our operations with new machinery, new processes, and new materials to meet your evolving needs.

It’s all part of a culture of commitment to your needs that you’ll find only when you partner with Gallagher . . . where you can be confident that you’ll always have your toughest demands – delivered.