Contouring Polyurethane Parts

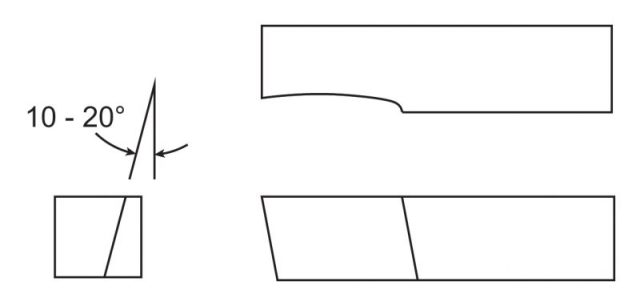

Machining tapers, chamfers, grooves, and other surface configurations into wheels, rollers, and other round parts all fall into the general category of contouring.

The tool works best when positioned .025 to .075 inches (.6 to 2 mm) below the center of the work-piece. The chips should come off in a continuous ribbon. Try to keep the chip from wrapping around the work-piece. If this occurs, stop, remove the urethane that wrapped around the work. Reduce the feed rate.

Safe fixturing of parts when contouring is very important. When contouring urethanes softer than 95A, use a tool with 15 to 30 degrees of top rake. Lathe speed depends on the O.D. of the part. In general, high rpm works best. Feeds should be slow until experience is achieved.

Note: When machining urethane, wear a full face mask.

Why Choose Gallagher For Your Cast Custom Urethane Needs?

Continuous Advancements in Polyurethane Expertise and Equipment

Bring Gallagher even the trickiest requirements of your most important components, and time after time, we turn them into success at our 100,000-square-foot, ISO-certified facility in Gurnee, Illinois. Meanwhile, as your demands keep getting tougher, we’re always reinvesting in our business, constantly enhancing our expertise and continuously improving our operations with new machinery, new processes, and new materials to meet your evolving needs.

It’s all part of a culture of commitment to your needs that you’ll find only when you partner with Gallagher … where you can be confident that you’ll always have your toughest demands – delivered.