Introduction to Polyurethane Elastomers

What Are Polyurethane Elastomers?

Polyurethane elastomers (urethane elastomers) are one type of a large family of elastic polymers called rubber.

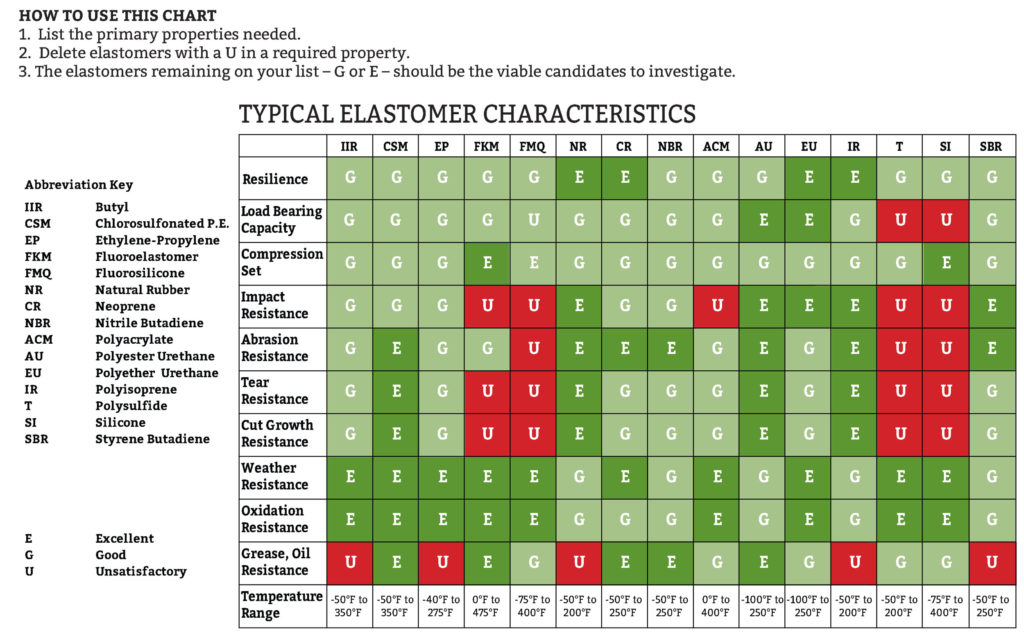

There are 14 types of rubber in general use. All of these polyurethane elastomers have been commercially successful, but they are all different in several ways. The chart below provides a quick initial screening guide of these polyurethane elastomers.

Isocyanates

- Toluene Diisocyanate (TDI)

- Diphenylmethane Diisocyanate (MDI)

- Paraphenylene Diisocyanate (PPDI)

- Toluidine Diisocyanate (TODI)

- 1,5-Naphthylene Diisocyanate (NDI)

Polyols

- Polyester

- PPG Polyether

- PTMEG Polyether

- Polycaprolactone

- Polycarbonate

Curatives

- 1,4-Butanediol (BD)

- 1,3-Propanediol

- Ethacure 300

- HQEE

- MOCA

While Gallagher Corporation has the technical expertise and equipment to process any of these materials, the combinations most typical to Gallagher include:

- TDI Polyester with hardness ranging from 70A to 70D

- MDI Polyester with hardness ranging from 85A to 95A

- TDI PTMEG Polyether with hardness ranging from 90A to 70D

- MDI PTMEG Polyether with hardness ranging from 60A to 95A

- TDI Polycaprolactone with hardness ranging from 60A to 55D

- NDI Polyester (Vulkollan®) with hardness ranging from 65A to 60D

TDI Polyester materials cured with MOCA produce tough elastomers that have outstanding abrasion resistance and excellent oil and aliphatic solvent resistance.

MDI Polyester materials cured with 1,4-Butanediol produce FDA wet and dry food grade urethanes which are tough, abrasion and tear resistant.

TDI PTMEG Polyether materials cured with MOCA have excellent low-temperature flexibility, excellent dynamic properties are resistant to microbial attack and hydrolysis.

MDI PTMEG Polyether materials cured with 1,4-Butanediol have high resilience (even at low temperatures), great dynamic properties, outstanding hydrolysis resistance and improved resistance to impingement type abrasion. Some MDI Ethers can be formulated to be FDA wet and dry food approved.

TDI Polycaprolactone materials cured with MOCA have better hydrolysis resistance than other polyesters while maintaining great resistance to abrasion. These materials also have great tear strength even at low hardness.

NDI Polyester cured with 1,4-Butanediol is trademarked with the name Vulkollan®. Vulkollan® is an ultra-high performance material that has the highest mechanical load bearing ability and is the best choice in highly dynamic applications.