Castable urethane raw materials are liquid, which permits them to be pumped, metered, mixed and dispensed by machines under very precise control of temperature and ingredient proportions. Castable urethanes enter molds…(read more)

Material selection is a vital aspect when it comes to producing cast polyurethane components. However, once the material is selected, more design work takes place to actually produce the cast polyurethane part…. (read more)

The electrical properties of polyurethane elastomers most commonly measured are as follows: Resistivity Dielectric Strength Dielectric Constant Power Factor Materials suitable for electrical insulators have high… (read more)

Unusually high levels of stress and deformation can occur in structures, machinery and other equipment due to shock or impact loads. When one rigid member strikes another, stress levels spike because there is no… (read more)

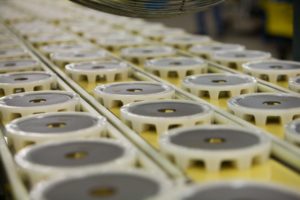

Insert molding is possible with either cast or injected molded polyurethane processes. We can mold to inserts such as bearings, wheel and roller hubs, threaded fasteners, metal plates, and shafts. The insert can…… (read more)

One of the most advantageous features of molding castable polyurethane is bonding it to other materials. Here at Gallagher Corporation, we are experts in bonding cast polyurethane to metals and other substrates…. (read more)

The elastic nature of polyurethanes makes them ideal candidates for applications where continuous flexing is experienced. However, when an elastomer is flexed continuously, failure generally occurs due to the development and propagation… (read more)

Molded polyurethane has excellent load bearing capacity and abrasion resistance. But, polyurethane also stands up very well in a large variety of environments. Understanding… (read more)

When a material is deformed, a certain amount of energy is required to achieve deformation. Recovery from deformation also takes a certain amount of energy. For polyurethanes, the ratio of energy… (read more)

Why is determining shear modulus for polyurethane parts important? Elastomers are typically used in shear for parts such as mounting brackets and suspension assemblies. These types of applications are chosen because… (read more)

Do you understand the difference between thermoset urethane and thermoplastic urethane? Either type is useful for OEM applications. But, certain applications are better suited for one over the other. Thermoplastic Polyurethane (TPU) is a. . . (read more)

Polyurethane elastomers will degrade due to prolonged ultraviolet (UV) light exposure. The UV light targets certain chemical linkages depending on the type of chemistry used for a particular compound. When a part….. (read more)

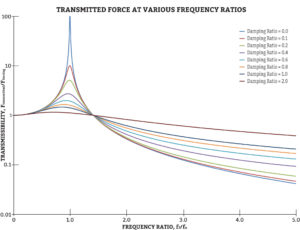

The dynamic properties of urethane in combination with its high load bearing capacity make it an excellent choice for a number of vibration isolation applications. The first step in understanding how urethane can be used to… (read more)

Vulkollan® is one of the most powerful elastomers in the market, combining highest mechanical load-bearing characteristics with highest dynamic load-bearing capacity. Therefore, Vulkollan® is preferably used for superior tasks in many… (read more)