Polyurethane’s Dimensional Tolerance

The acceptable variance in the dimensions of a manufactured product

Why It Matters

Manufacturing to tight dimensional tolerances can be the difference in making a urethane component that works flawlessly. On the other hand, moderate tolerances can reduce manufacturing cost. We’ll work with you to find the right balance between tight and moderate tolerances.

The Gallagher Advantage

Polyurethane’s dimensional tolerances can be tight. Our molding typically provides a precision of ± 1% of the dimension of interest, or ± 0.254 mm ( ± 0.010 in), whichever is greater. Depending on the product size and shape, we can mold to tolerances as tight as ± 0.127 mm (± 0.005 in). If the project calls for even tighter tolerances, we can CNC machine or grind the molded product.

But note that not every project requires the polyurethane’s dimensional tolerances to be tight. Identifying the loosest acceptable tolerances can reduce manufacturing cost. Looser tolerances are also more accommodating to possible thermal expansion or volume increase due to water absorption that polyurethane components may exhibit as a result of your application’s environment. We will assist you with accounting for possible volume increase in your product’s design.

How We Do It

We meet tolerance requirements through a combination of precise control over the molding process, secondary machining operations, and a robust set of quality inspections.

Process Control

Our commitment to precision begins with the design and engineering of the mold and, if applicable, the bonded insert. When the tightest tolerances are required, we use precision machining and hardened steel.

Process control throughout the molding process is how we truly achieve precision. A chemical reaction takes place during molding. Any deviations to that reaction could impact the end product’s dimensions or performance properties. Raw material ratios, temperature, and time are key factors of the process. We precisely control these with advanced processing equipment, automated processes, and recurring process calibrations.

We ensure that we deliver the same high quality over repeated production runs. Each project’s processes are documented, and then we train and operate accordingly. We are certified to ISO 9001:2015.

Secondary Machining

If tolerances are required that are tighter than what we can effectively mold to, then we can CNC machine or grind the molded product. Our in-house machine shop is equipped to do the machining and grinding. Plus we have over 50 years of experience in performing these specialized operations.

Quality Inspection

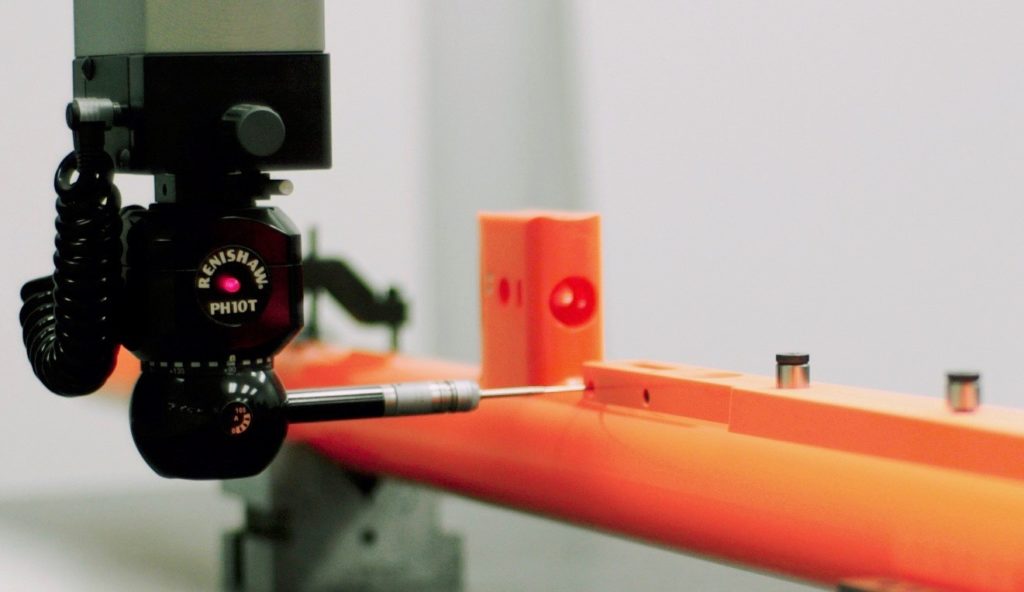

Our approach to quality is all-inclusive. It starts with a rigorous first article test to qualify not only the first article, but also the mold and the molding process. As we move into full production, we incorporate in-process and final inspections. Our inspections use a coordinate measuring machine (CMM) for precise measurements, a micro-Vu for when non-contact measurements are better, and a host of other test equipment.