Polyurethane’s Compression Set

The permanent deformation that remains after the removal of a deforming compressive force

Why It Matters

Polyurethane’s compression set is an important property to consider when your component must endure a compressive load. Examples of applications include bumpers, equipment mounts, vibration isolation pads, and rollers. Urethane’s compression set indicates how well the polyurethane will retain its elastic properties under compression.

A compound with low compression set will recover quite well, even if maintained in a compressed state for an extended period of time. Conversely, a compound with a high compression set will not recover as well. It will permanently retain much more of the deflection upon removal of the compressive stress.

Polyurethane’s compression set depends on a combination of basic properties such as modulus and the degree of molecular cross-linking, which result from the polyurethane’s formulation. We can tailor the polyurethane’s resistance to compression set to fit your specific need.

Measurement

Urethane’s compression Set is expressed as a percentage related to the amount of permanent deformation caused by the compressive load.

We select the best test method based on the nature of the intended application. The tests are more applicable to service conditions involving static stresses.

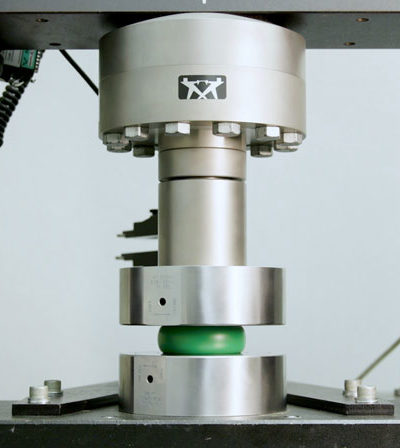

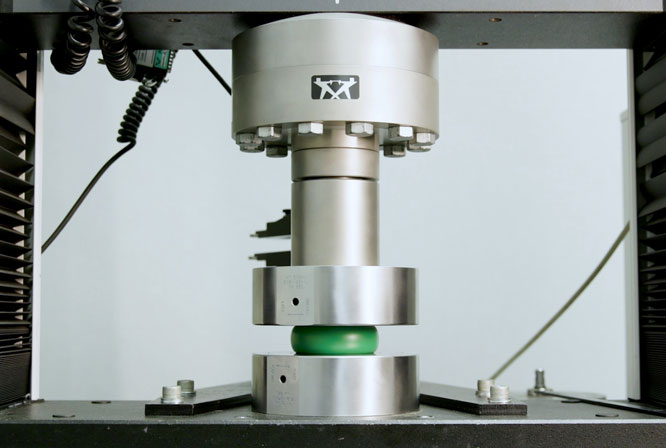

ASTM D-395 – Standard Test Method for Rubber Property – Compression Set is commonly used for measuring compression set of polyurethane. Tests are conducted for a prescribed period of time at an elevated temperature. Typical values are 22 hours at 70°C (158°F). The specimen is then allowed to recover at room temperature for 30 minutes. Finally, the permanent deformation of the test specimen is measured.

The ASTM test has two different methods.

- Constant Force, sometimes referred to as Method A. This test compresses a test specimen between parallel rigid plates under a constant stress. Then compression set is calculated as a percentage of the specimen’s permanent deformation to its original thickness.

- Constant Deflection, sometimes referred to as Method B. This test compresses a test specimen between parallel rigid plates to 75% of its original thickness. Then compression set is calculated as a percentage of the specimen’s permanent deformation to the applied deflection.

Typical Values

The lowest compression set is achieved with highly cross-linked urethanes.

Polyurethane’s compression set typically ranges from 5-40%.