Need Custom Polyurethane Wheels or Polyurethane Rollers?

Don't Worry, We've Done This A Million Times

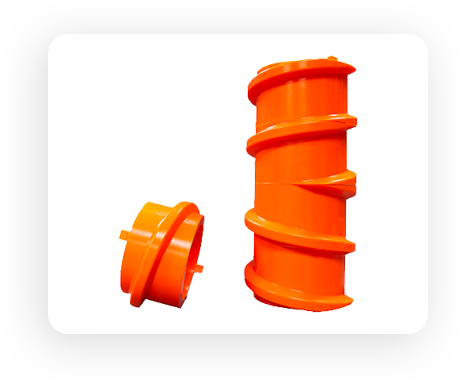

We collaboratively design, precisely mold, and dependably deliver polyurethane wheels and rollers that improve your product’s performance

We supply OEMs with custom polyurethane wheels and polyurethane rollers

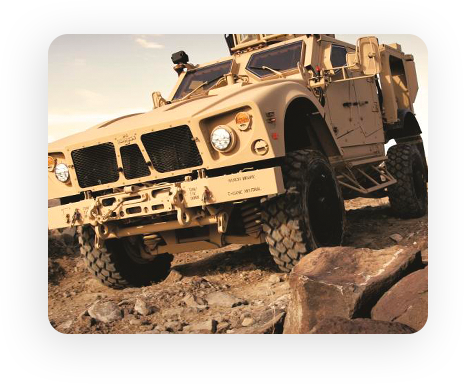

It doesn’t matter if you do conveyors, warehouse robots, tractors, forklifts, escalators, or any of the million other applications. It also doesn’t matter if you have an application that requires drive, idler or guide wheels/rollers.

We focus on producing high quantities of custom urethane wheels and urethane rollers. We lead our industry in using automation. With our automated processes, we have the efficiency, capacity, and precision to manufacture wheels and rollers by the thousands.

Why “custom”?

Because off-the-shelf products may not deliver the performance or fit that you need. Custom polyurethane wheels and polyurethane rollers offer:

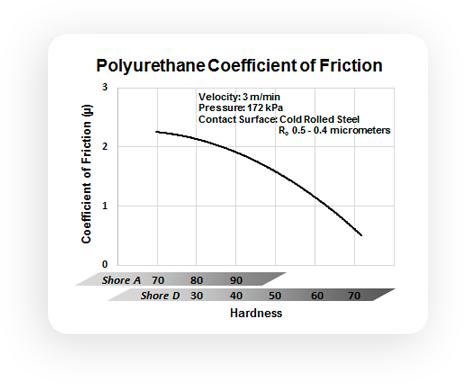

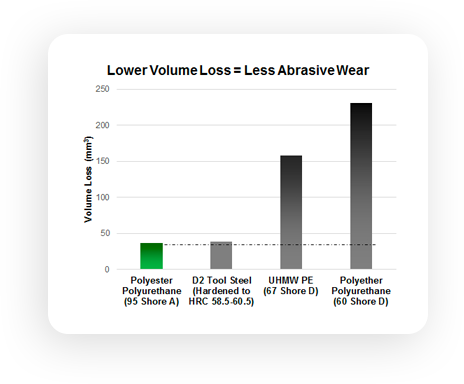

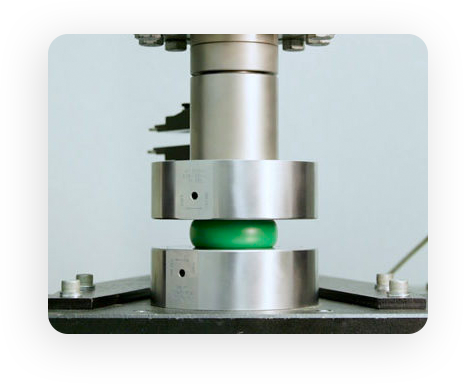

- Performance properties that are tailored for your application

- Bearings or hubs that are bonded in

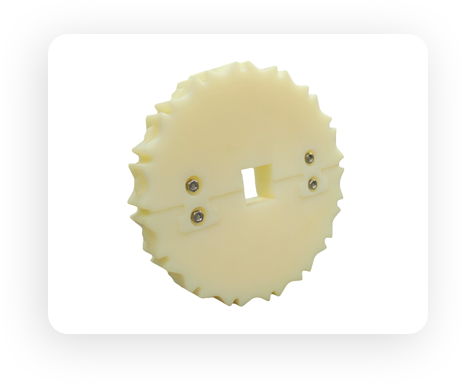

- Complex tread and hub geometries

- Traceability through direct part marking

- Your logo on the product

Here’s What We Can Do for You

Here’s What We Can

Do for You

For a custom polyurethane wheel or roller, we can help with design, engineering, and test aspects. Or you may have an existing wheel or roller design that is already working for you, and you’re just looking for a new supplier. Either way, we’re ready to accelerate your polyurethane wheel or polyurethane roller project into production.