Polyurethane Durometer

A material’s resistance to localized deformation

Why It Matters

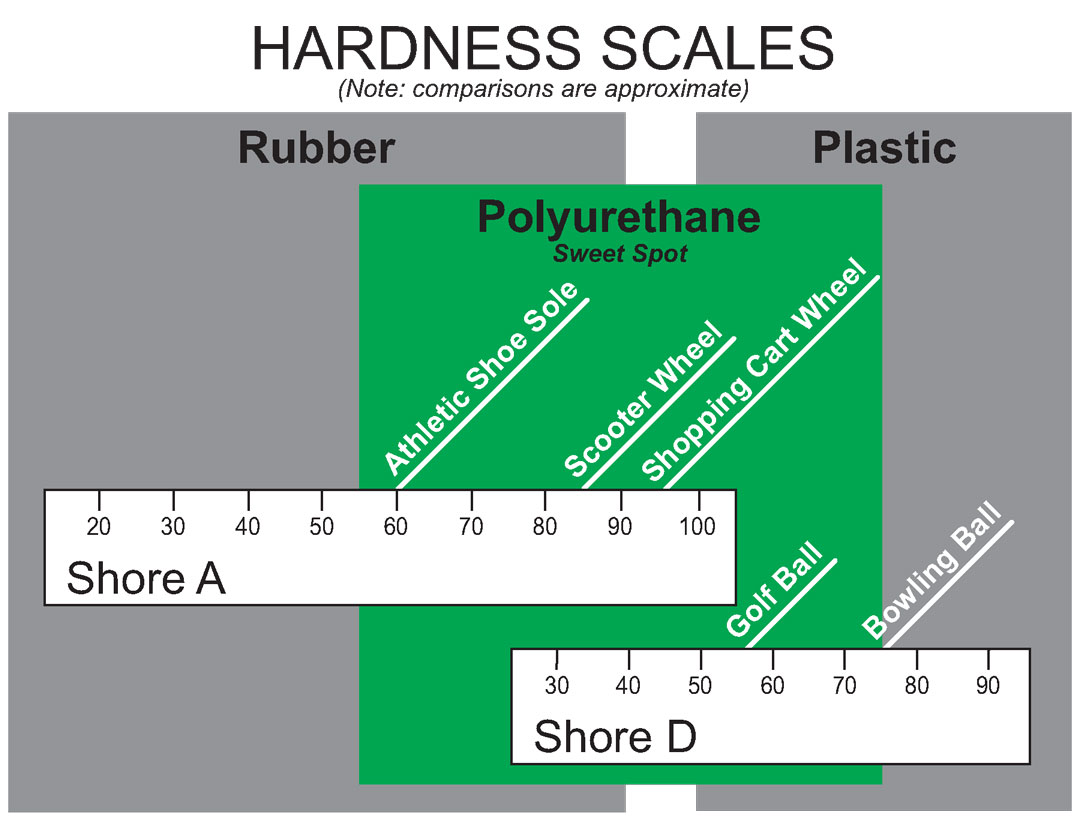

Polyurethane delivers excellent performance across a hardness range that spans from approximately athletic shoe sole (low hardness) to bowling ball (high hardness). Polyurethane’s hardness range straddles typical rubber and plastic hardnesses. Many applications – from shock absorbers to wheels to wear pads – take advantage of polyurethane’s unique combinations of performance and hardness. Polyurethane durometer is another way of saying polyurethane hardness.

Hardness is an indicator of a material’s modulus. But hardness alone is not a good specifier of a polyurethane’s overall performance. Different polyurethane formulations can have the same hardness, yet have a very different set of performance properties. So don’t rely on just hardness to specify a polyurethane.

Polyurethane’s durometer is dependent on the specifics of the formulation. We can tailor the polyurethane’s hardness to fit your specific need.

Measurement

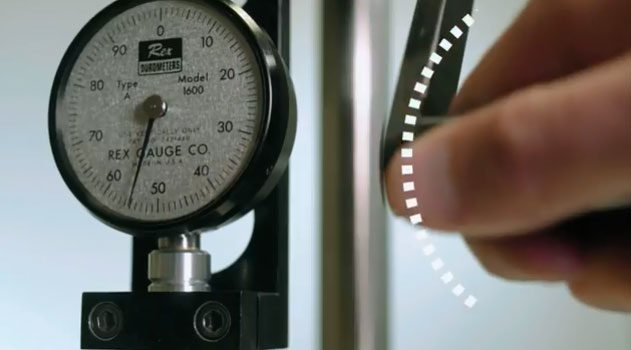

Hardness is a dimensionless quantity. Polyurethane durometer, or hardness, is measured on various overlapping scales. The most popular scales for measuring polyurethane hardness are Shore A and Shore D. Shore OO or Rockwell R scales might be used for very low or very high hardness measurements, respectively. Converting between hardness scales is not recommended.

Shore scales range from 0 (soft) to 100 (hard). An instrument called a durometer measures Shore hardness. It forces a conical-shaped indenter into the surface of the material and then measures the depth of the indentation. The material’s hardness is inversely related to the depth of penetration. ASTM D-2240 – Standard Test Method for Rubber Property – Durometer Hardness – further describes the process for measuring hardness.

Typical Values

Urethane’s hardness has a wide range from very soft, like a gel bicycle seat (~25 Shore OO), to very hard, like a bowling ball (~75 Shore D). But the sweet spot for many of its performance properties occurs from 55 Shore A to 75 Shore D. This is where we tend to see the most potential for polyurethane.