Custom Polyurethane Rollers & Wheels

Don't Worry, We've Done This A Million Times

Gallagher Corporation is a leading custom polyurethane wheels manufacturer serving design engineers, operations leaders, and procurement managers across North America. For over 60 years, our 175,000-sq-ft ISO-certified facility in Gurnee, Illinois, has delivered precision-engineered urethane wheels and custom polyurethane rollers that outperform rubber and metal alternatives in demanding industrial applications.

Custom polyurethane wheels and rollers are precision-molded elastomer components designed to handle extreme loads, resist abrasion, and provide superior performance in material handling, manufacturing, and industrial equipment. Unlike standard rubber wheels that wear quickly or metal rollers that generate noise and vibration, polyurethane delivers an optimal balance of durability, resilience, and customization. Our U.S.-based manufacturing combines advanced automation with hands-on material science expertise to produce custom urethane wheels and rollers tailored precisely to your application specifications.

Why Choose Custom Polyurethane Wheels and Rollers?

Custom polyurethane wheels and custom urethane rollers deliver measurable performance advantages that directly impact equipment efficiency, operational costs and production uptime. Understanding these benefits helps procurement teams justify investments and operations leaders plan for long-term asset performance.

- Exceptional durability and wear resistance

- Superior load-bearing capacity

- Outstanding vibration damping

- Cost efficiency over equipment lifetime

- FDA and industrial-grade formulations

- Performance properties that are tailored for your application

- Bearings or hubs that are bonded in

- Complex tread and hub geometries

- Traceability through direct part marking

- Your logo on the product

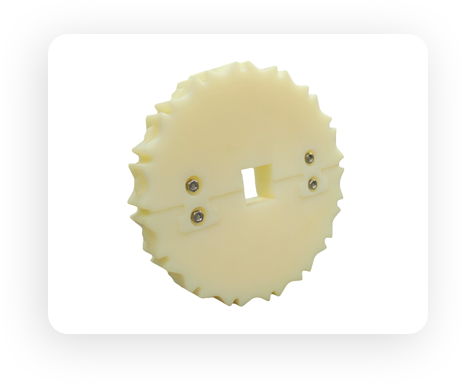

Custom Gallagher Polyurethane Wheels – Designed for Your Application

Industrial Applications

Custom urethane wheels from Gallagher serve critical functions across industries where standard components fail. Our engineering team has developed specialized designs for material handling systems, conveyor applications, AGV stackers, food processing equipment, printing machinery, and automotive manufacturing.

Material handling environments benefit from wheels providing durability for high-cycle operations while maintaining precision positioning. Past applications include forklift drive wheels handling 10,000-pound loads, escalator wheels operating 24/7 for years, and specialized caster wheels for medical equipment.

Types of Gallagher Custom Polyurethane Wheels

- Drive Wheels: Engineered for power transmission with consistent traction and torque delivery

- Idler Wheels: Support loads and reduce friction in non-powered applications

- Concave Radius Wheels: Specialized profiles guide belts, cables. or round materials with precision

- Urethane-Covered Bearings: Integrated bearing assemblies with precision-molded polyurethane

- Dual Durometer Wheels: Combine hardness levels in one component for unique performance

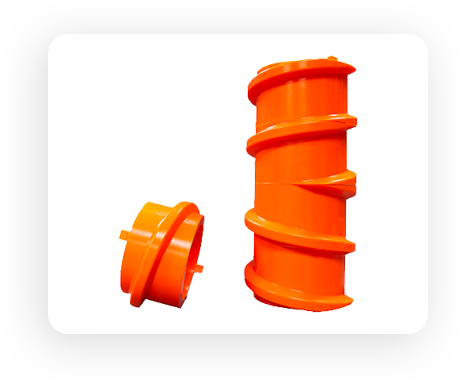

Custom Polyurethane Rollers for Industrial Precision

Types of Rollers We Manufacture

- Idler Rollers: Support converyor systems with low rolling resistance

- Drive Rollers: Transmit power efficieently while maintaining traction

- Feed Rollers: Control material flow with consistent surface contact

- V-Groove & U-Groove Rollers: Guide cylindrical materials, cables or pipes

- Nip Rollers: Press materials together in laminating and coating applications

- Large-Diameter & Specialty Rollers: Up to 50 in. in diameter

Design & Material Options

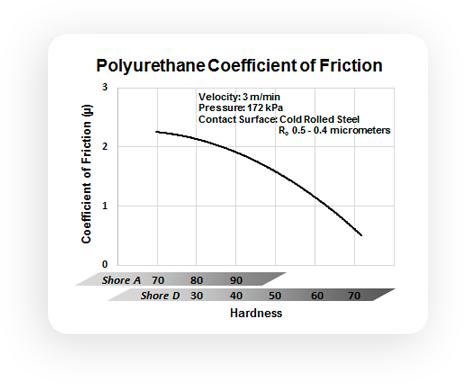

Gallagher’s formulations span 60A to 75D Shore hardness, allowing optimization for load capacity, surface protection, traction, and operating conditions based on resilience characteristics.

Choosing optimal formulation involves evaluating load requirements, operating speed, chemical exposure, temperature range, abrasion resistance and coefficient of friction requirements.

Specialized Additives: UV stabilizers for outdoor applications, anti-static additives for electronics manufacturing, wear-resistant additives extending service life, low-friction additives minimizing rolling resistance, and pigments maintaining appearance.

Manufacturing Capabilities and Quality Assurance

All design, engineering, tooling, molding, machining, and finishing occur at our Northern Illinois facility. Domestic manufacturing eliminates international shipping delays and provides direct engineering access. ISO-level quality systems document every manufacturing stage.

In-house capabilities include mold design and fabrication, core machining in steel and aluminum, multiple casting technologies, precision grinding, and assembly services. Our extensive tooling library often provides existing molds that substantially reduce initial tooling investment.

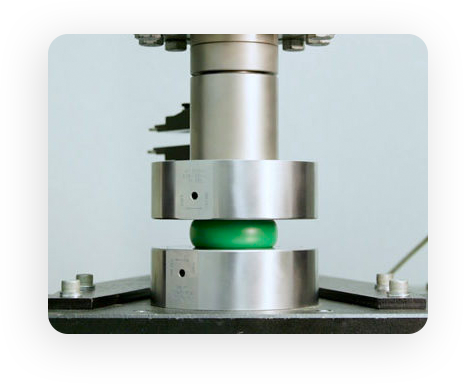

Every component undergoes durometer testing, concentricity measurement, surface finish verification, dimensional inspection, and bond strength testing.

Polyurethane Formulations & Performance Options

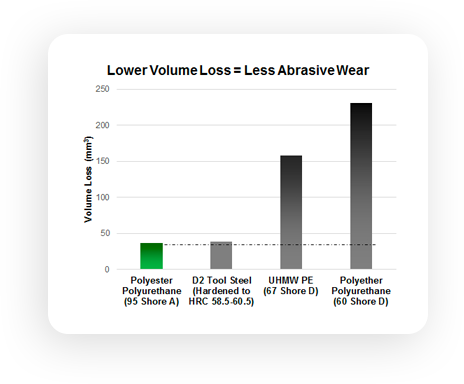

Polyether-based formulations provide excellent hydrolysis resistance for applications involving water exposure. Polyester-based formulations offer superior mechanical properties, including higher tensile strength and better abrasion resistance.

High-performance materials deliver industry-highest load capacities and exceptional wear life. Specialized grades include high-load capacity, abrasion-resistant, chemical-resistant, FDA-compliant, and anti-static formulations.

Industries Served

Gallagher polyurethane rollers and wheels provide performance advantages across diverse applications:

- Material Handling: Conveyor systems, sortation equipment, package handling

- Industrial Equipment: Manufacturing machinery, production line components

- Transportation: Forklift wheels, escalator rollers, elevator components

- Food Processing: FDA-compliant formulations for wet and dry food contact

- Exercise Equipment: Precision rollers for commercial fitness machines

- Agricultural Equipment: High-load applications requiring durability in harsh environments

Design & Engineering Support

From concept to CAD modeling, engineers work as an extension of your design team. FEA software models stress distribution, load bearing, and deformation characteristics, informing durometer selection and geometric optimization.

Engineers consult on polyurethane chemistry selection, durometer specification, core material and design, surface finish requirements, and testing protocols. While competitors supply products to specifications, Gallagher partners with engineering teams to optimize designs.

Frequently Asked Questions

Custom polyurethane wheels and custom urethane rollers serve material handling and logistics, food and beverage processing, automotive manufacturing, printing and converting, packaging equipment, industrial machinery, mining and agriculture, robotics and automation, medical equipment, and aerospace and defense applications.

Versus rubber, polyurethane provides four times higher load-bearing capacity, abrasion resistance lasting up to 10 times longer, a wider hardness range, and better chemical resistance. Versus nylon, polyurethane offers superior vibration damping, lower noise generation, better traction, and customizable properties.

Softer durometers (60 to 80A) provide maximum shock absorption and noise reduction. Medium durometers (80 to 95A) balance load capacity with resilience. Harder durometers (95A-75D) deliver maximum load-bearing capacity. Our engineering team can calculate optimal durometer and recommend to validate the selection.

Strip and re-coat services include complete removal of worn polyurethane, core inspection and repair, surface preparation, fresh polyurethane application, precision grinding, and quality testing.

Projects requiring new tooling need 4 to 6 weeks for initial samples. Production orders with existing tooling generally ship in 3 to 4 weeks.

Request a Quote for Custom Polyurethane Wheels & Rollers

Transform equipment performance with custom polyurethane wheels and custom urethane rollers engineered for your application. Gallagher’s 60 years of manufacturing expertise, in-house engineering support, and ISO-certified quality systems ensure components meet specifications and deliver performance.