Vibration Damping and Vibration Isolation with Polyurethane

The absorption and dissipation of vibration energy (vibration damping), and the reduced transmission of vibration energy (vibration isolation)

Why It Matters

Vibration can lead to equipment fatigue and damage, poor machinery performance, and audible noise. You can mitigate these impacts by adding polyurethane vibration damping or isolation components. Urethane is a great choice for such components, especially for high-load applications with medium to high-frequency vibration. Examples are machinery mounts and feet, pads, and bumpers.

Polyurethane’s viscoelastic nature is key to its passive damping action. Each cycle of vibration causes strain and friction within the polyurethane. This converts mechanical energy into thermal energy (see hysteresis). Energy dissipates as heat is released. This energy dissipation will damp out free vibration.

Limiting heat build-up within urethane due to vibration is an important design consideration. Vibration with high frequency and/or large amplitude will cause more heat build-up. Heat build-up can be minimized by designing for lower strains to create less heat, and by designing to better dissipate that heat.

A lot of engineering goes into designing a polyurethane vibration damping component or a polyurethane vibration isolation component. We can help you. Contact us today to get started on a project!

Measurement

Dynamic Mechanical Analysis (DMA) measures vibration damping characteristics over a wide temperature range. The DMA test dynamically strains a material sample to measure both its storage modulus and loss modulus. When polyurethane is strained, some of the energy is stored (“storage modulus”) due to polyurethane’s elastic nature. Likewise, some energy is lost as heat (“loss modulus”) due to its viscous nature. A new term, “loss factor,” is the ratio of loss modulus to storage modulus. Polyurethane’s damping ratio is approximately half its loss factor.

Typical Values

Values for vibration damping and vibration isolation are specific to the application, so it’s only possible to provide general ranges. Specifics like polyurethane properties, component design, input vibration characteristics, preload condition, and temperature will determine actual performance.

Vibration Damping

Damping ratio is a measure of effectiveness. It is the amount of actual damping relative to the critical damping value. Critical damping is the damping state that provides the quickest return to equilibrium. By definition, its damping ratio equals 1. An underdamped system is more common, and shows progressively decaying oscillations. An underdamped damping ratio is less than 1.

Polyurethane damping ratios are underdamped. They typically range from 0.05 to 0.15, but theoretically could get as high as 0.5. Higher damping ratios come from polyurethanes with higher loss factors. Polyurethane’s damping ratio is approximately equal to half its loss factor (for loss factors less than 0.2 and in their linear region).

Vibration Isolation

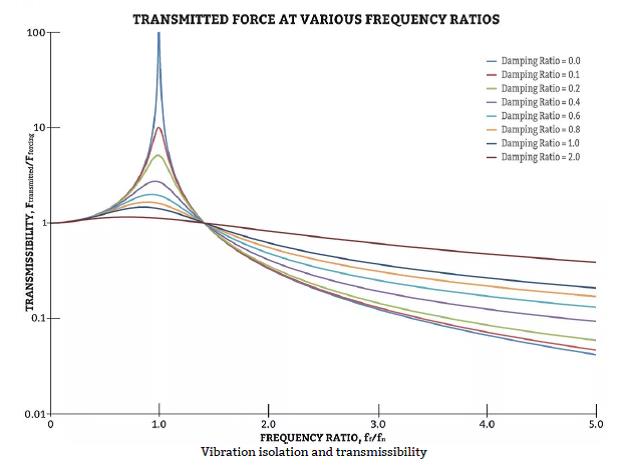

Transmissibility of an isolation component is also a measure of effectiveness. It is the percent of input vibration that gets transmitted. Your transmissibility goal should be based on the fragility of the equipment you are protecting.

Transmissibility can be estimated using frequency ratio, damping ratio and this transmissibility curve. The curve shows a cross-over from amplification to isolation at a frequency ratio of about 1.4. A frequency ratio greater than 2 is typically used for vibration isolation components.

Frequency ratio is the forcing frequency relative to the isolator’s natural frequency. An isolator’s natural frequency depends on its preload deflection.