Polyurethane Shape Factor

Let’s look at the shape factor and how it applies to polyurethane.

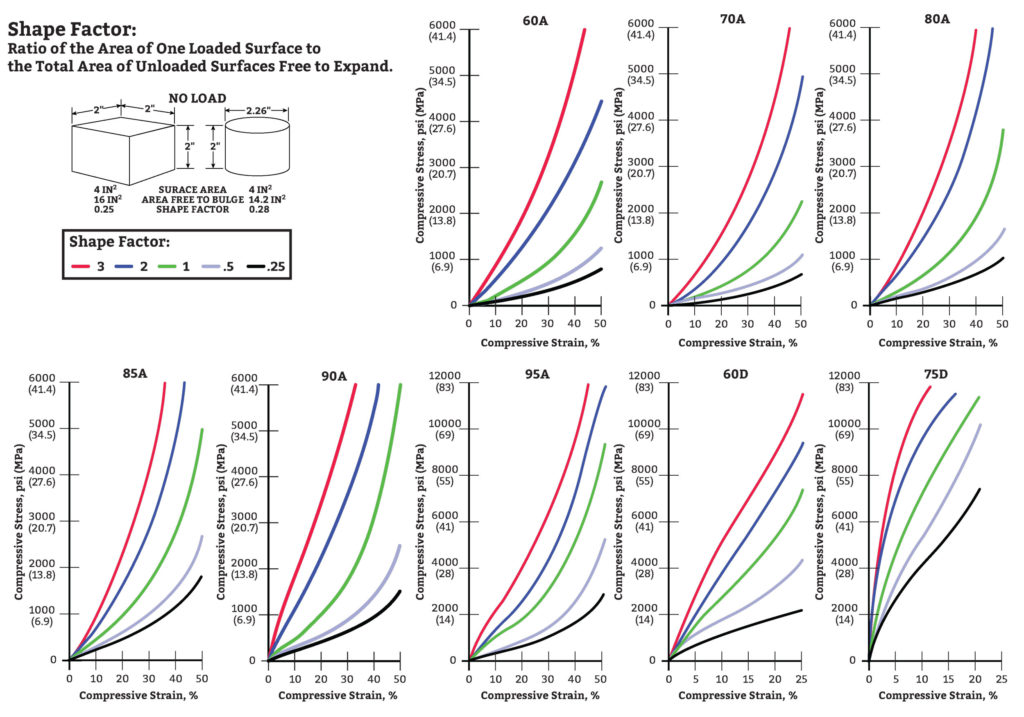

The compression-deflection relationship is modified by the shape of the part. The shape has only a minor effect in tension and shear.

For example, consider two blocks of urethane. One is a cylinder, the other is a block of the same height and the same cross-sectional area but is rectangular rather than circular. Both blocks are made from the same compound and the top and bottom surfaces are bonded to metal. If the same weight is placed on each block, the deflection will be greater for the rectangular block than for the cylindrical block. Neither block loses perceptible volume during deflection; they bulge at the sides that were perpendicular to the top and bottom surfaces. The area under the load is the same for each block, but the area of the side walls (the total area free to bulge) on the rectangular block is greater than the side wall area of the cylinder – thus increasing the area free to bulge, making bulging easier and permitting greater vertical displacement.

The influence of shape is substantial and can be expressed numerically as shape factor (SF).

Shape factor is the ratio of one loaded surface area to the total area free to bulge. Parts of the same compound and shape factor behave almost identically in compression, regardless of the actual shape, provided the pieces have parallel loading faces, whose thickness is not more than two times the smallest linear dimension (to prevent buckling) and top and bottom surfaces are not free to move laterally.

How to Use Polyurethane Shape Factor in Design

Polyurethane shape factor is a simple concept. In elastomer design for compression, it is critical. Keep in mind that elastomers behave like incompressible hydraulic fluids. Under load, they do not change volume. The following charts and series of examples show how polyurethane behaves under load and how you calculate the polyurethane shape factor.

Shape Factor Examples

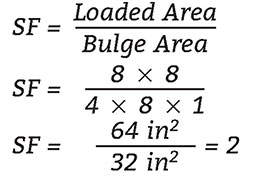

Example 1: Assume a urethane pad 8″ square by 1″ thick, made of 90A durometer (GC 1090) compound. How much will the pad deflect under a load of 128,000 pounds?

(A) The shape factor of the pad is:

(B)![]()

(C) On the 90A durometer graph on the curve for a shape factor of 2.0 we note that 2,000 psi produces a 17% deflection. Therefore, the pad will deflect about 0.17″ under this load.

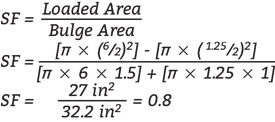

Example 2:

The largest impact cushion which can be used is 6″ diameter and 1.5″ thick. There must be a 1.25″ diameter counter bored hole, 1″ deep, in the center for attachment. How much impact can this cushion take repeatedly at 5% deflection?

(A)

(B) The highest load-bearing capacity at 5% deflection is attainable with the 70D durometer compound (GC 1575)

(C) At a shape factor of 0.8, we could expect to handle about 4,500 psi compressive stress. Therefore, the pad will take approximately 121,000 pounds at a deflection of 5% or 0.075

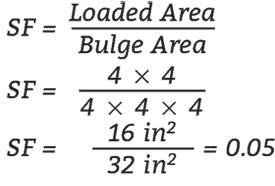

Example 3:

What compound to choose for a 4″ square pad by 2″ thick to handle a 10,000 lb. load. The pad should be able to deflect 1/4″.

(A)

(B) A deflection of 13% on a 2″ thick pad is .25″.

(C)![]()

(D) Checking the 0.5 shape factor curves, we see that at 13% deflection, the 95A durometer (GC 1095) compound comes closest with about 700 psi (11,000 pounds total).

Design Recommendations

Maximum Strain For Compressive Loading

| Hardness | 60A | 75A | 80A | 85A | 90A | 95A | 60D | 70D |

|---|---|---|---|---|---|---|---|---|

| Static Load, Long Term | 15% | 15% | 15% | 15% | 10% | 10% | 5% | 2% |

| Dynamic Service (0.32 Hz) | 25% | 20% | 20% | 15% | 15% | 10% | 5% | 5% |

| Dynamic Service (0.16 Hz) | 35% | 35% | 35% | 25% | 25% | 20% | 10% | 5% |

Design Recommendations

Maximum Strain For Compressive Loading

| Hardness | 60A | 75A | 80A | 85A | 90A | 95A | 60D | 70D |

|---|---|---|---|---|---|---|---|---|

| Static Load, Long Term | 15% | 15% | 15% | 15% | 10% | 10% | 5% | 2% |

| Dynamic Service (0.32 Hz) | 25% | 20% | 20% | 15% | 15% | 10% | 5% | 5% |

| Dynamic Service (0.16 Hz) | 35% | 35% | 35% | 25% | 25% | 20% | 10% | 5% |

These are approximations for “average” service conditions. Please check with us for specific application recommendations.