Polyurethane’s Coefficient of Friction

The ratio of the friction force between two bodies and the normal force pressing those bodies together

Why It Matters

Friction resists the relative motion of two bodies sliding against each other. Friction, and therefore coefficient of friction (COF), can either help or oppose what you want to do in your application.

Low polyurethane coefficient of friction is desirable for applications that want sliding to occur. Example applications include slide bearings, bushings and wear liners. On the other hand, high polyurethane coefficient of friction is desirable for applications that want minimal slippage between surfaces. An example of this type of application is a drive wheel.

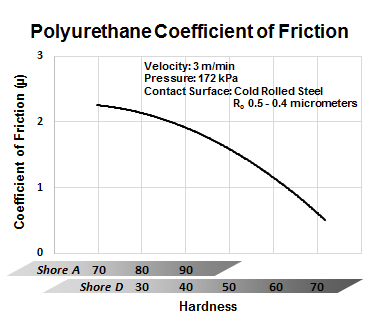

The coefficient of friction between two bodies depends on system variables like the materials of both bodies, their surfaces’ roughness, and the relative velocity between the bodies. For polyurethane, its hardness is also a key factor. In addition to changing hardness, urethane’s coefficient of friction can also be modified by including additives in the formulation. We can tailor urethane’s coefficient of friction to fit your specific need.

Measurement

Coefficient of friction is dimensionless.

ASTM D-1894 – Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting is commonly used for measuring COF of polyurethane. The test measures the force required to pull one material across another. The force required to initiate motion is used to calculate the static COF. The force required to maintain a uniform motion is used to calculate the kinetic COF.

Typical Values

Polyurethane’s Coefficient of Friction is similar to that of rubber.

In general, harder polyurethanes have a lower COF, and softer polyurethanes have a higher COF. In typical polyurethane applications, the kinetic COF ranges from 0.2 to 2.5.