Is Urethane Plastic?

“Is Urethane Plastic?” Good question – simple answer. “NO”.

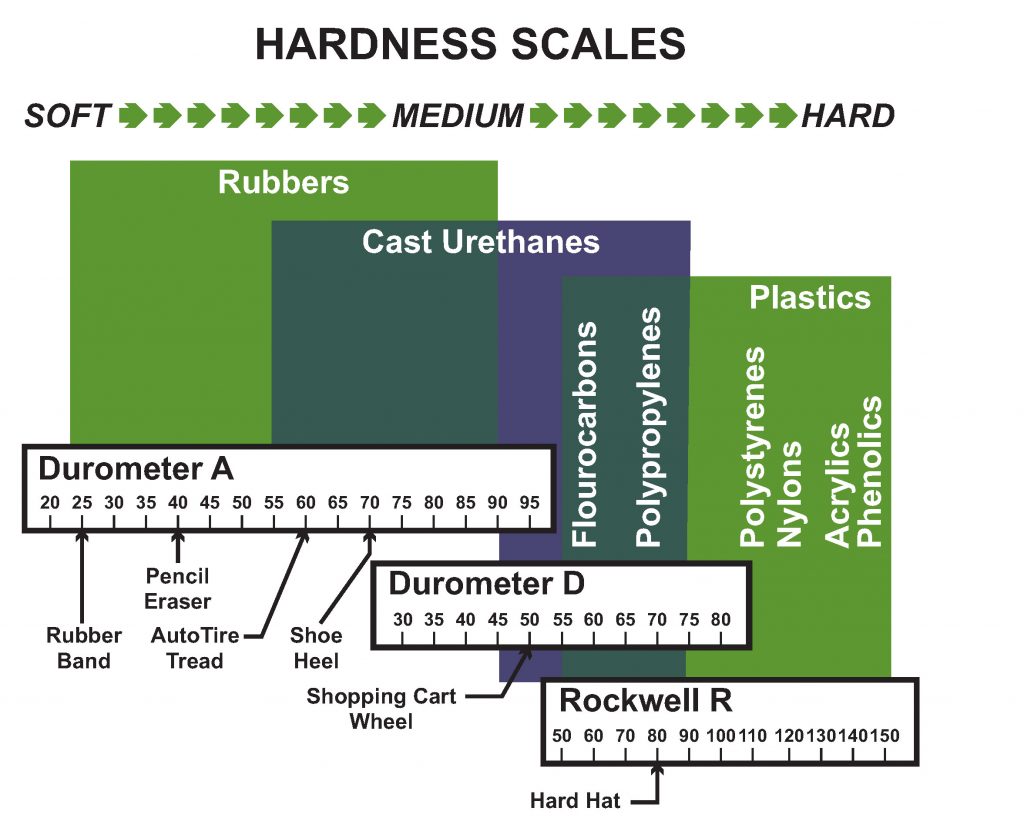

Let’s first understand the definition of durometer. Durometer is a measure of a material’s hardness – a material’s resistance to permanent indentation.

With plastics, the higher the durometer, the more likely a part will crack or break under impact or shock loading.

On the other hand, urethane is not brittle. It has elastic properties capable of significant resistance to impact – even at higher durometers. Urethane retains its elasticity and strength. Urethane can be stretched significantly and still return to its original shape.

There are ten major groups of urethanes:

- MDI-Polyesters: produce FDA dry and wet food grade urethanes in the normal hardness range from 85 Durometer A to 45 Durometer D. They are tough, abrasion resistant and tear resistant.

- TDI-Polyester: produces urethanes from 50 Durometer A to 75 Durometer D which are tough, abrasion resistant, and with excellent oil and aliphatic solvent resistance.

- MDI-Polyethers: produce urethanes with higher resilience, better impingement type abrasion resistance, good dynamic performance, improved hydrolysis resistance and excellent low temperature properties. Some are adaptable to FDA and USDA application for wet and dry food contact.

- TDI-Polyethers: have excellent low temperature and dynamic properties, microbial resistance and long term water resistance.

- TODI Polycaprolactone: Excellent heat resistance, hydrolysis resistance and superior mechanical properties/

- PPDI: Terminated polyesters and polyethers offer superior performance at higher temperatures.

- MDI: Diphenylmethane Diisocyanate

- TDI: Toluene Diisocyante

- PPDI: Paraphenylene Diisocyanate

- TODI: Toluidine Diisocyanate

Taken together, urethanes possess:

- Oil, water and weather resistance, ozone and oxidation resistance, and resistance to many chemicals. Some are radiation, fungus and bacteria resistant.

- High tensile and tear strength compared to other elastomers.

- Outstanding abrasion resistance compared to metals, plastics and other elastomers.

- Higher load bearing capacity than other elastomers. Higher impact resistance and resilience than plastics.

- Excellent retention of properties at very low temperatures and at temperatures up to 220°F (104°C). (Bonded to metal to 160°F (71°C).