Define Polyurethane

We are often asked to “Define Polyurethane”.

We are often asked to “Define Polyurethane”.

For the most part, when thinking about polyurethane, the common thought is in relation to putting a clear coat on some piece of furniture.

At Gallagher, there’s a bit more to consider when coming up with an answer to the question of “Can you define polyurethane?”.

Polyurethanes are one type of a large family of elastic polymers called rubber. Unlike conventional rubber, polyurethanes start out as liquids and can be cast in low-pressure molds. Here at Gallagher, we also process thermoplastic urethanes that lend themselves well to injection molding.

What polyurethene should you be using?

The polyurethanes processed at Gallagher are typically two-component systems: a prepolymer and a curative. We also process compounds with three and sometimes four components to achieve specific properties. For our thermoset compounds, the prepolymers and the curatives are held in separate tanks under vacuum in our meter mix machines. When it’s time to make a part, the prepolymer and curative are mixed and dispensed into a mold. In the mold, a chemical reaction takes place which forms the solid elastomer. The thermoplastic urethanes we use for injection molding are different from the thermoset polyurethanes and are fully reacted prior to our processing operation.

The polyurethanes processed at Gallagher are typically two-component systems: a prepolymer and a curative. We also process compounds with three and sometimes four components to achieve specific properties. For our thermoset compounds, the prepolymers and the curatives are held in separate tanks under vacuum in our meter mix machines. When it’s time to make a part, the prepolymer and curative are mixed and dispensed into a mold. In the mold, a chemical reaction takes place which forms the solid elastomer. The thermoplastic urethanes we use for injection molding are different from the thermoset polyurethanes and are fully reacted prior to our processing operation.

The prepolymers used for urethane processing consist of isocyanate groups that react with either hydroxyl groups or amine groups in the curative. The resultant moiety from the isocyanate-hydroxyl reaction is called a urethane linkage; isocyanate-amine reaction forms what are called a urea linkage. As more and more isocyanate groups in the prepolymer link up with hydroxyl or amine groups in the curative, many urethane linkages are formed and this is where the term polyurethane comes from.

There are many combinations of prepolymers and curatives available which create unique properties in the cured urethane elastomer. Prepolymers are distinguished by the type of isocyanate and the type of polyol that is used to make them. The type of isocyanate used in the prepolymer is the main building block of the polyurethane compound. Here at Gallagher we typically use four different types of isocyanate: MDI, TDI, TODI, and PPDI. Other types are available and we can offer those for specialized applications. The major groups of polyol consist of Polyester, PTMEG Polyether, and Polycaprolactone. Each type will produce an elastomer with unique properties.

Define polyurethane? Contact us to learn more about the polyurethane formulations we can use to solve the unique challenges of your application.

About Polyurethane

About Polyurethane

Polyurethanes are one type of a large family of elastic polymers called rubber. Unlike conventional rubber, polyurethanes start out as liquids and can be cast in low-pressure molds. Here at Gallagher, we also process thermoplastic urethanes that lend themselves well to injection molding.

What polyurethane should you be using?

The polyurethanes processed at Gallagher are typically two-component systems: a prepolymer and a curative. We also process compounds with three and sometimes four components to achieve specific properties. For our thermoset compounds, the prepolymers and the curatives are held in separate tanks under vacuum in our meter mix machines. When it’s time to make a part, the prepolymer and curative are mixed and dispensed into a mold. In the mold, a chemical reaction takes place which forms the solid elastomer. The thermoplastic urethanes we use for injection molding are different from the thermoset polyurethanes and are fully reacted prior to our processing operation.

The prepolymers used for urethane processing consist of isocyanate groups that react with either hydroxyl groups or amine groups in the curative. The resultant moiety from the isocyanate-hydroxyl reaction is called a urethane linkage; isocyanate-amine reaction forms what are called a urea linkage. As more and more isocyanate groups in the prepolymer link up with hydroxyl or amine groups in the curative, many urethane linkages are formed and this is where the term polyurethane comes from.

There are many combinations of prepolymers and curatives available which create unique properties in the cured urethane elastomer. Prepolymers are distinguished by the type of isocyanate and the type of polyol that is used to make them. The type of isocyanate used in the prepolymer is the main building block of the polyurethane compound. Here at Gallagher we typically use four different types of isocyanate: MDI, TDI, TODI, and PPDI. Other types are available and we can offer those for specialized applications. The major groups of polyol consist of Polyester, PTMEG Polyether, and Polycaprolactone, each type will produce an elastomer with unique properties.

What Are Polyurethane Elastomers?

Polyurethane elastomers (urethane elastomers) are one type of a large family of elastic polymers called rubber.

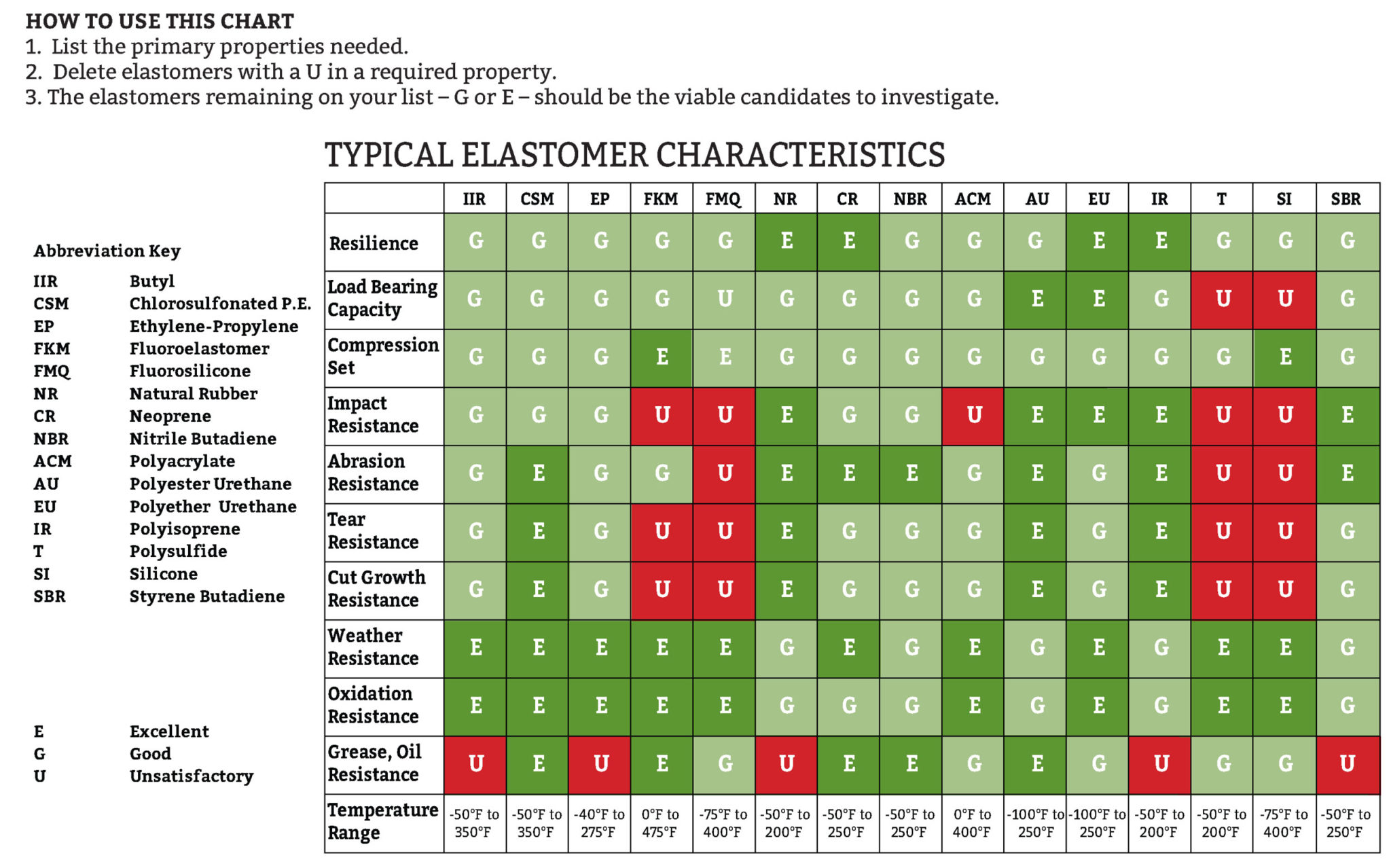

There are 14 types of rubber in general use. All of these polyurethane elastomers have been commercially successful, but they are all different in several ways. The chart below provides a quick initial screening guide of these polyurethane elastomers.

Download this table as a PDF

Custom Cast Urethane Manufacturer Capabilities at a Glance

Custom Cast Urethane Manufacturer Capabilities at a Glance

- Custom molding of cast polyurethane

- Product design and development

- Moldmaking and machining

- Injection molding – thermoplastic polyurethane (TPU), thermoplastic elastomers, and glass reinforced plastics

- ISO 9001:2008 certified

About Polyurethane

About Polyurethane