Think Of Us As Your

Competitive Advantage.

We’re ready to help whether your project is build-to-print or new development, is mass production or low quantity, or demands maximum performance.

We’re ready to help whether your project is build-to-print or new development,

is mass production or low quantity, or demands maximum performance.

is mass production or low quantity, or demands maximum performance.

We Are Experts

We know polyurethane, how to mold it, and how to turn it into products. Which means that we can unlock the potential of polyurethane to solve your challenges.

Tailored Performance

We control the science of polyurethane to give you an advantage. We formulate and process the polyurethane chemistry to provide performance parameters that best meet your requirements.

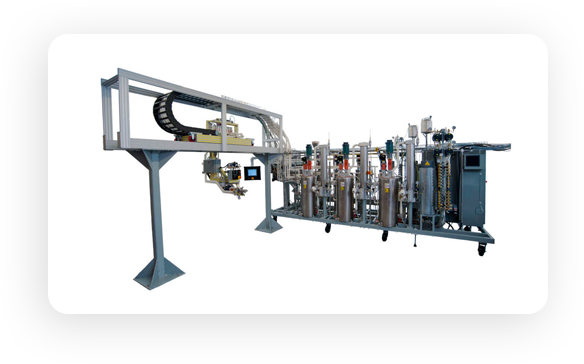

Molding Expertise

We mold complex shapes, hold tight tolerances, and reliably bond polyurethane to metals, plastics, and composites.

End-To-End Product Manufacturing

Our in-house capabilities enable us to make your polyurethane product from start to finish. Being a turnkey polyurethane manufacturer creates time and cost savings for us, and therefore for you.

We Deliver

Superior products dependably delivered. We deliver quality polyurethane products on time – from prototypes to millions.

Product Satisfaction

Our quality management system, process controls, and test capabilities ensure greater than 99% product satisfaction.

High Volume Production

We lead polyurethane manufacturers in using automation, which enables our efficiency, capacity, and precision.

On-Time Delivery

We commit to a delivery schedule, and then we deliver on time better than 97% of the time. And the other 3% of the time? Challenges happen in making custom products, but we always overcome.

We Are Partners

Together we’ll achieve success. As your polyurethane manufacturer, we’ll help you lead your market.

Collaboration

We collaborate with you to fully understand your engineering challenge and design goals, to develop innovative solutions, and to advance from prototype into production.

Continuous Improvement

We strive to continuously improve to support a successful and long-term partnership. This means working with you to improve your product’s performance and reduce its cost, as well as improving our capabilities with new formulations, new equipment, and improved processes.

Trusted Partner

Trust provides an enduring foundation for success. You can trust our commitment to open communication, integrity, safety, and the environment.

A Message From Our President and CEO

We are passionate about developing and delivering polyurethane products that solve your demanding challenges.

Polyurethane is up to the task. It is an amazing material with versatility – in fact, we tailor its performance properties to match your specific application. This makes molded polyurethane the ultimate engineering material.

But a great material does not, by itself, make great solutions. Solutions must be smartly designed and developed to satisfy their intended applications. And then, to actually make an impact, those solutions must be manufactured and delivered. We do all that and more.

Our people are urethane experts and, when partnered with you, are great at applying urethane to solve your challenges. We have optimized and controlled every process to ensure precise chemistry from start to finish.

Together, our people and processes achieve the highest performance levels and produce the best products of any polyurethane manufacturer — bar none.

To stay on top, we continue to innovate and we never sacrifice integrity, safety, quality, or the environment. These are core values that we live by. My promise to you is that we will dependably deliver superior products that solve your demanding challenges.

Leverage Our Capabilities

We utilize the most advanced urethane processing equipment, maximize process automation, and invest in our engineering and test capabilities. Our workforce has over 900 years combined of experience — and we continuously train to renew our skills. These capabilities put us in the lead of urethane manufacturers and translate into superior product quality and production capacity.

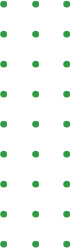

Advanced Processing Equipment

- Superior process control & quality

- Precise blending of formulations

- High production capacity

Automated Manufacturing Processes

- Superior process control & quality

- Cost efficiency

- High production capacity

Product Engineering & Testing

- Innovative designs

- Iterative development

- Superior quality

Stay Ahead, Because We’re Staying Ahead

We are participating members of several key trade and manufacturing associations. Our involvement in these organizations keeps us informed and leaning forward in areas like: technology, health and safety, the environment, and evolving regulations.

Polyurethane Manufacturers Association (Charter Member)

Illinois Manufacturers’ Association

National Association of Manufacturers